TBD Pharmatech combines modern infrastructure with disciplined process know-how to execute every stage of a small-molecule CDMO program — from early route design to commercial GMP manufacture or structured tech transfer.

-

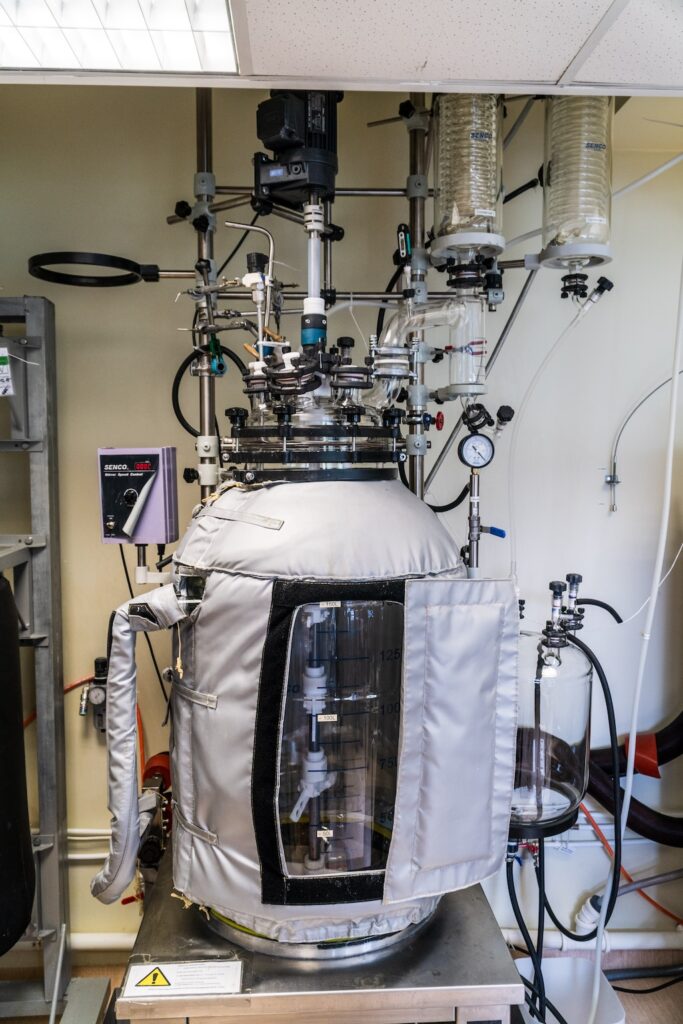

Multi-Step Synthetic Chemistry – broad reaction toolkit (acid/base, metal-catalysed, high-pressure) operated under tightly controlled temperature and pressure ranges.

-

Process Engineering & Scale-Up – Transfer from gram benches to multi-hundred-kilogram GMP suites.

-

Purification & Isolation – filtration, centrifugation, crystallisation, and vacuum drying technologies that secure high purity and low residual solvent.

-

Analytical Sciences – full suite of chromatographic, spectroscopic, and solid-state techniques for method development, validation, stability, and release testing.

-

Process Safety & Containment – risk assessments, calorimetry, segregated flows, and ATEX-rated equipment to handle energetic or potent chemistries safely.

-

GMP Documentation & Regulatory Support – preparation of batch records, validation protocols, and CMC/DMF filings overseen by Qualified Persons.

-

Structured Tech Transfer – formal knowledge capture, gap analysis, engineering demos, and validation runs that embed external processes into our quality framework.